Concentration And Vacuum Evaporator

We are a leading Manufacturer & Exporter of Concentration And Vacuum Evaporator such as Evaporator and Vacuum Pan / Evaporator from India.

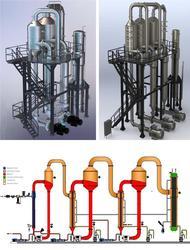

Evaporator

Designed for the concentration of tomato and fruit juices (apricot, peach, apple, pear, orange, etc.) by the water evaporation contained into the product.

The evaporated water is eliminated through cooling water into the condenser.

Designed for the concentration of tomato and fruit juices (apricot, peach, apple, pear, orange, etc.) by the water evaporation contained into the product.

The evaporated water is eliminated through cooling water into the condenser.

The concentration plants are available in various models:

• Single Effect

• Double Effect

• Triple Effect

The evaporation is carried out under vacuum to reduce evaporation temperature.

In the single effect the steam coming out from product is conveyed directly to the condenser, while in the multiples effect is reutilized to evaporate additional product in the following stadium.

The concentration plant is provided of:

• Vertical exchanger ( steam – product )

• Evaporation chamber

• Connection plant where the product recirculates through centrifugal pumps

• Mixing water condenser

• Electric control panel

All made in stainless steel.

The concentration plant is equipped with Refractometer that measure continuously the Brix concentration and pilot the outlet product discharge, level controlling loop for each stadium, steam feeding and trap.

Production range:

inlet fresh product: 1.000 – 20.000 Kgs/hour

Concentration Range: 7°-37° Brix.

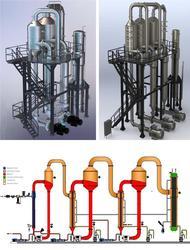

Vacuum Pan / Evaporator

The main body of the vacuum pan is in AISI 304 quality stainless steel; with the hemispherical bottom suitably jacketed in a stainless steel /mild steel jacket designed for working steam pressure upto 3 kg/cm2.

The main body of the vacuum pan is in AISI 304 quality stainless steel; with the hemispherical bottom suitably jacketed in a stainless steel /mild steel jacket designed for working steam pressure upto 3 kg/cm2.

The anchor type slow speed stirrer is fitted with Teflon scrapers for efficient heat transfer & minimizing risk of charring.

Supplied complete with vertical condenser in mild steel, condenser extraction pump, water ring vacuum pump, operating platform with catwalk & ladder, sampling device, observation ports, hand ole for cleaning, & necessary steam fittings, etc.

Conventional, versatile equipment suitable for virtually any vacuum concentration application, e.g. tomato juice, mango pulp, guava juice, banana pulp, fruit jam, etc., to achieve a high degree of concentration which is not possible by other means.

The evaporation capacity will depend on the type, viscosity & quality of product.

Depending upon the capacity requirement, multiple units can be supplied in parallel working arrangement.

With necessary modifications, the unit can be supplied as a double effect continuous concentration or particularly for concentration of tomato juice.

Single effect/double effect vacuum concentration units using vacuum pans to suit various applications, can be offered on request.

Three Standard Models:

• Model 1 – 450 liters holding

Capacity of hemispherical bottom

• Model 2 - 750 liters holding

Capacity of hemispherical bottom

• Model 3 – 1000 liters holding

Capacity of hemispherical bottom

Water evaporation capacity:

• Model 1 – Up to 200 Kgs per hour

• Model 2 - Up to 350 Kgs per hour

• Model 3 - Up to 475 Kgs per hour

Concentration And Vacuum Evaporator

Evaporator

Evaporator

Designed for the concentration of tomato and fruit juices (apricot, peach, apple, pear, orange, etc.) by the water evaporation contained into the product. The evaporated water is eliminated through cooling water into the condenser.

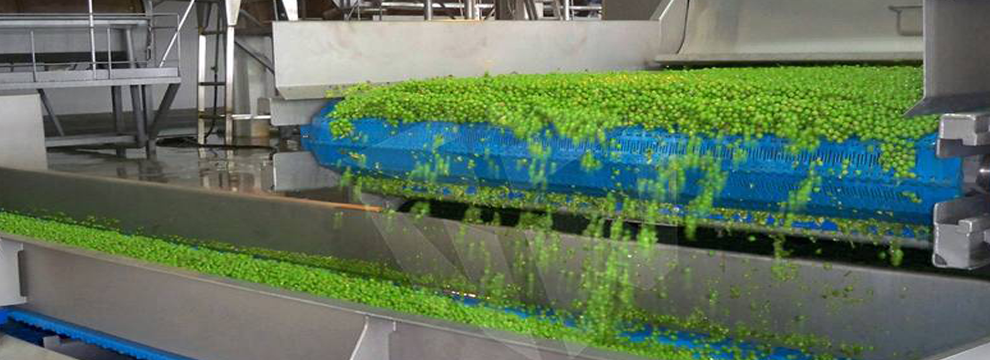

Application

• Designed for the evaporation of products with high content of solid matter and / or high viscosity.

• Tomato juice concentrate

• Fruit concentrate

• Tropical fruit concentrate (Mango, Papaya etc.)

• Berry fruit concentrate (Strawberries, blueberries, etc.)

• Applicable to all food industry sectors where some water content needs to be eliminated from the raw material while keeping its organoleptic properties unaltered.

Evaporation is the elimination of the solvent, in form of vapor, from a solution. For most evaporation systems, the solvent is water and the heat is provided by steam condensation. Therefore, vapor is the unwanted by product and could be recovered (or not) in accordance to its energy value. Thus, evaporation is normally carried out by evaporation a portion of the solvent, producing a concentrated solution.

The Concentration Plants are available in various models :-

• Single Effect

• Double Effect Forced Circulation Evaporators

• Triple Effect

The evaporation is carried out under vacuum to reduce evaporation temperature. In the single effect the steam coming out from product is conveyed directly to the condenser, while in the multiples effect is reutilized to evaporate additional product in the following stadium.

The Concentration plant is provided of :-

• Vertical exchanger (steam – product)

• Evaporation chamber

• Connection plant where the product recirculates through centrifugal pumps

• Mixing water condenser

• Electric control panel

All made in stainless steel. The concentration plant is equipped with Refractometer that measure continuously the Brix concentration and pilot the outlet product discharge, level controlling loop for each stadium, steam feeding and trap. Production range: inlet fresh product: 1.000 – 20.000 Kgs/hour Concentration Range: 7°-37° Brix.

Designed for the concentration of tomato and fruit juices (apricot, peach, apple, pear, orange, etc.) by the water evaporation contained into the product.

The evaporated water is eliminated through cooling water into the condenser.

Designed for the concentration of tomato and fruit juices (apricot, peach, apple, pear, orange, etc.) by the water evaporation contained into the product.

The evaporated water is eliminated through cooling water into the condenser.  The main body of the vacuum pan is in AISI 304 quality stainless steel; with the hemispherical bottom suitably jacketed in a stainless steel /mild steel jacket designed for working steam pressure upto 3 kg/cm2.

The main body of the vacuum pan is in AISI 304 quality stainless steel; with the hemispherical bottom suitably jacketed in a stainless steel /mild steel jacket designed for working steam pressure upto 3 kg/cm2. Evaporator

Evaporator